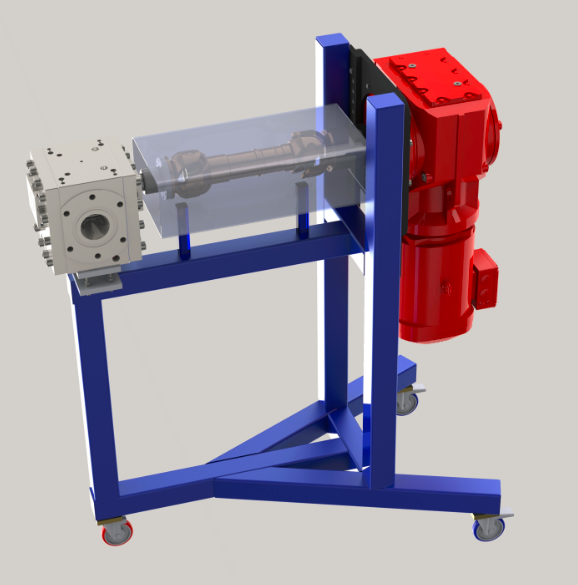

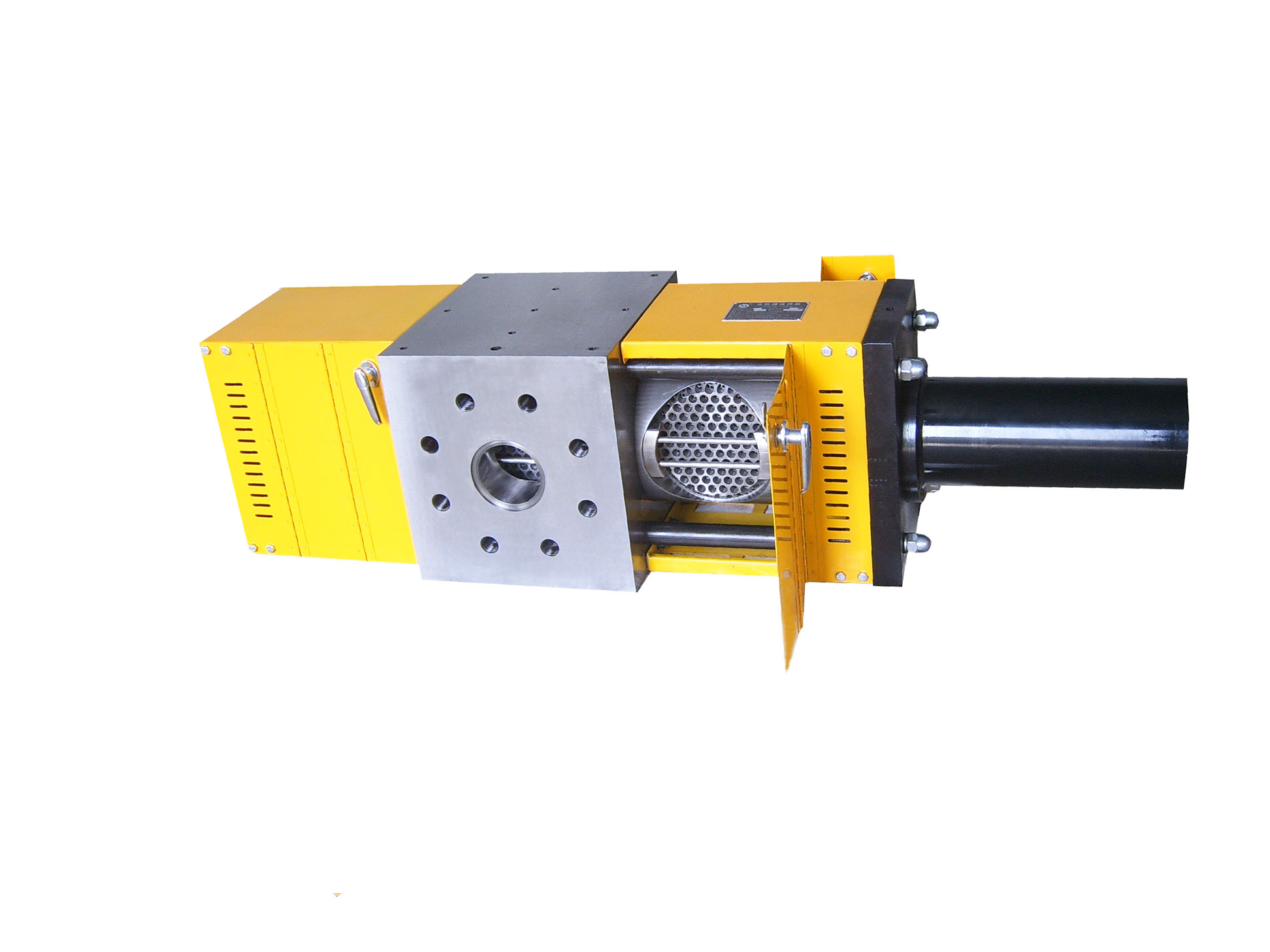

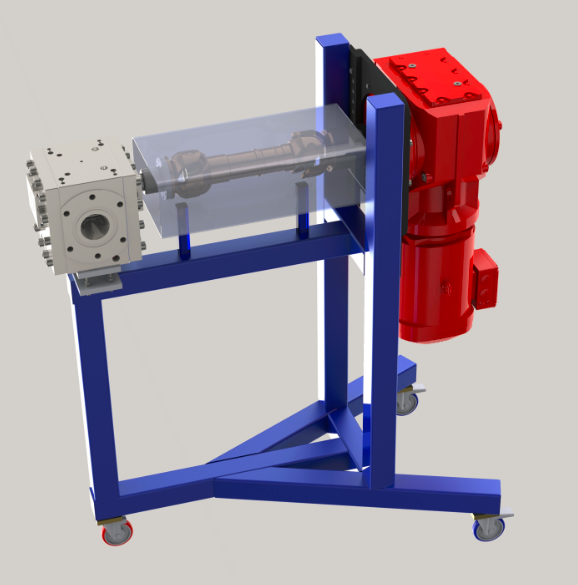

DE Series Melt Gear pump

Structure Specications:

Rotor type: helical or straight cylindrical gear Heating mode: electric heating / heat medium heating Sealing structure: melt dynamic sealing packing sealing Mechanical Seal with cooling Melt dynamic Seal The universal coupling is recommended to connect the reducer and melt pump to eliminate the influence of thermal deformation. The melt gear pump belongs to the volumetric forced conveying pump, which can adjust the output flow rate by adjusting the speed of the pump. The near linear flow output of gear pump can be realized.

Applications:

Suitable for extrusion transportation from low viscosity to very high viscosity polymer melt; generally installed between extruder outlet and die head as melt metering pump; can also be installed in polymer melt pipeline as booster pump; This series pump housing built-in runner, can be used for cooling or heat medium heating. Is a universal extrusion system melt gear pump. Body gear pump

Features:

1. The minimum pressure and flow pulsation can realize the linear output of the flow rate, which is suitable for the precision extrusion system. 2. For different working conditions using different structure and material configuration to better meet the personalized needs of users; 3. It can be used in the conditions of high temperature (350 ℃), high pressure (40 MPA) and high viscosity (400 Pa s). 4. Precision structure, high precision, long life.

Technical Parameters: