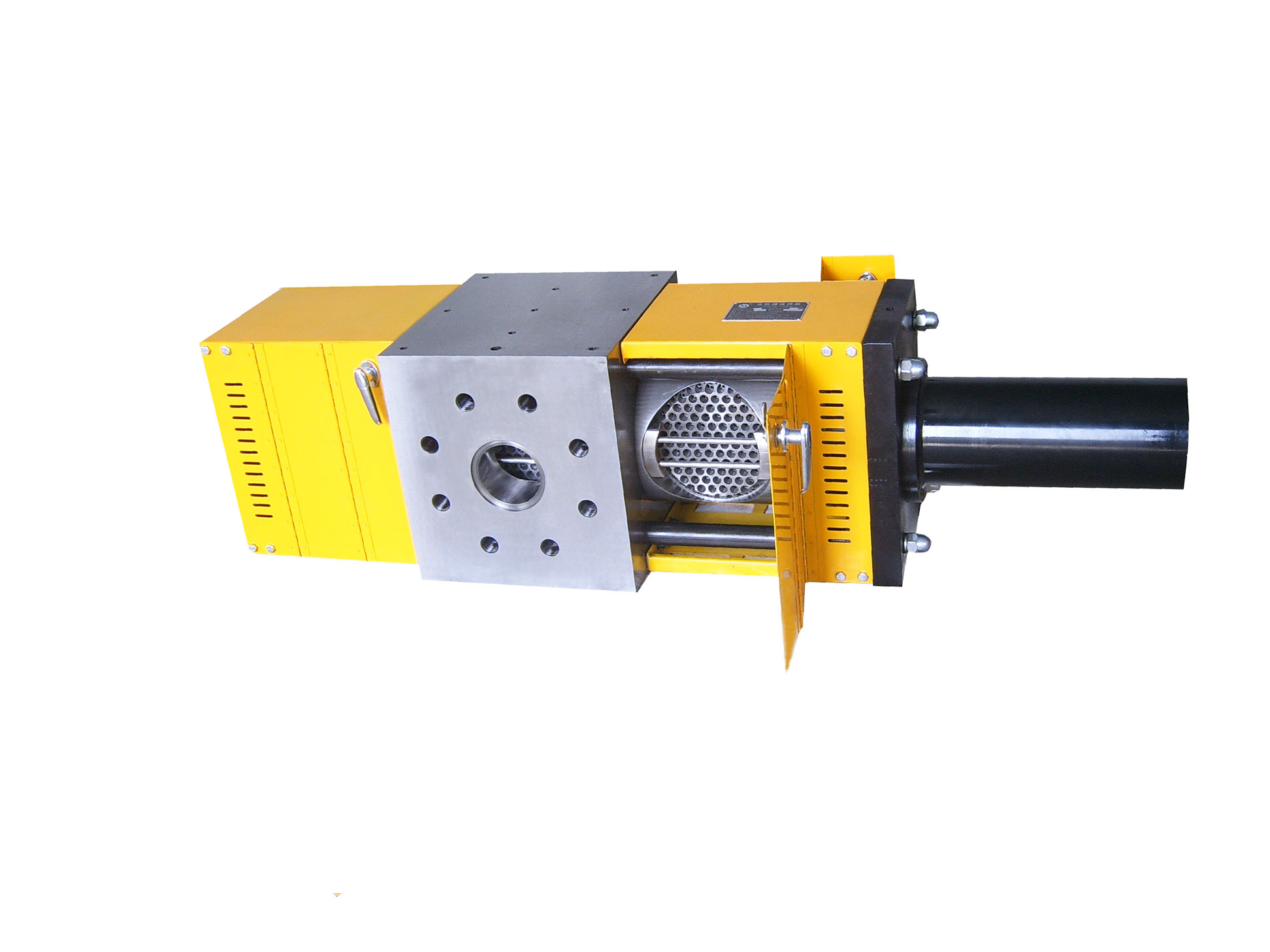

Melt Mixing and Filtrstion Combined XL Special Screen Changer

Structure Specications:

Pioneering XL screen changer in china , double working positions in separated structure , builtin oilcontrol and heating system , sealing system and channels perfectly combined , ensuring no material retention and homogenization temperature

Applications:

Widely applied in petrochemical synthetic resin prilling PS,PET,ABS,PE,PP,PEEK,and other major ethylene petrochemical project

Features:

1.Static mixing channel system contribute to homogenization of promoter and resin , better stabilization , longer service life 2.Enhanced flexible sealing technology , sealing pressure insrease as the melt pressure goes up , self-reimbursement when abrasion , no leaking 3.Fast hydraulic screen changing , simple and convenient

Technical Parameters:

| Type | Screen Diameter (mm) | Melt pressure (MPa) | Output (Kg/h) | Heating power (KW) | Weight (Kg) |

|---|---|---|---|---|---|

| ZM260B-T | Φ266*2 | ≤40 | ≤3500 | 油控Oil Control | 550 |

| ZM320B-T | Φ326*2 | ≤40 | ≤4500 | 油控Oil Control | 700 |

| ZM360B-T | Φ368*2 | ≤35 | ≤7000 | 油控Oil Control | 900 |

| ZM400B-T | Φ410*2 | ≤35 | ≤9000 | 油控Oil Control | 1100 |